Check with seller Mould Online Width Adjustment and Taper Measurement Wuhan

- Location: Wuhan, Hubei, China

Overview

In order to meet the needs of producing various specifications of continuously cast products, shorten the time for replacing the mold, and improve the production capacity and production efficiency of the continuous casting machine, the mold online width adjustment system is the key technology for efficient continuous casting. The online mold width adjustment system enables the two narrow sides of the continuous casting slab mold to move inward or outward in small steps until the predetermined width is reached. During the production process, the adjustment of the mold’s width can be completed without stopping the machine. Generally, the online width adjustment of the mold needs to be connected with the online taper measurement of the mold. Only with adjustment and detection can the online adjustment range of the mold be accurately controlled.

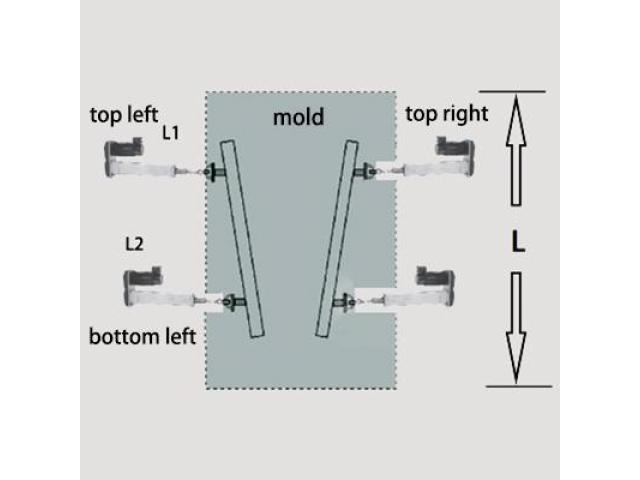

Fig 1 Mold online width adjustment system

The components of the system

Workstation: host system, system width adjustment control, taper detection.

On-site operation box: real-time display of the current control status, manual operation to adjust parameters.

Digital Electric Cylinder: Precise digital control of electro-hydraulic drive cylinder, which can achieve high-precision quantitative control.

On-line measurement of taper: Install it on the narrow-face copper plate of the mold, and monitor the taper of the narrow-face copper plate in real time. Cooperate with the detection feedback control of the width adjustment system, so as to achieve high-precision adjustment.

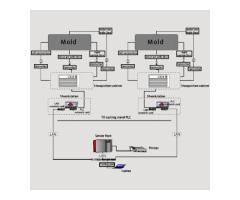

FIG 2 System block diagram

The technical parameters

Adjustable range: 0-1250mm (unilateral)

Control accuracy: 0.02mm/0.05mm/0.1mm

Step resolution: 0.01mm/0.02mm

Running speed: 0-10mm/s

Power: 3.5KWl

16-bit encoder: 65536 pulses

Weight: 25Kg

Shell: high-strength aluminum alloy

FIG 3 Syetem software interface

The functions of the system

Realize online width adjustment function

Realize the online real-time monitoring function of mold taper

Continuous casting production adjustment and non-stop production

One-key operation in the main control room, automatic completion

High adjustment accuracy and fast speed

The interlock control of the continuous casting steelmaking system can realize automatic steel pouring

Useful information

- Avoid scams by acting locally or paying with PayPal

- Never pay with Western Union, Moneygram or other anonymous payment services

- Don't buy or sell outside of your country. Don't accept cashier cheques from outside your country

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"

Related listings

-

Mold Oscillation Online Monitoring SystemEverything Else - Wuhan (Hubei) - January 28, 2024 Check with seller

Mold Oscillation Online Monitoring SystemEverything Else - Wuhan (Hubei) - January 28, 2024 Check with sellerOverview Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly cool the high-temperature molten steel continuously inj...

-

Mold Powder Thickness Detection SystemEverything Else - Wuhan (Hubei) - January 26, 2024 Check with seller

Mold Powder Thickness Detection SystemEverything Else - Wuhan (Hubei) - January 26, 2024 Check with sellerOverview: Mold powder is mainly used in the continuous casting and steelmaking process, evenly sprinkled on the molten steel surface in the mold to lubricate, keep warm, prevent oxidation and absorb non-metallic inclusions. Mold powder is an indispen...

-

Mold Breakout Prediction SystemEverything Else - Wuhan (Hubei) - January 26, 2024 200000.00 Dollar US$

Mold Breakout Prediction SystemEverything Else - Wuhan (Hubei) - January 26, 2024 200000.00 Dollar US$Overview: The BPS-K600 continuous casting mould breakout prediction system is developed by Wuhan CenterRise M&C Measuring Co., Ltd. It adopts artificial neural network and combines with traditional artificial intelligence and information processing t...